Product classification

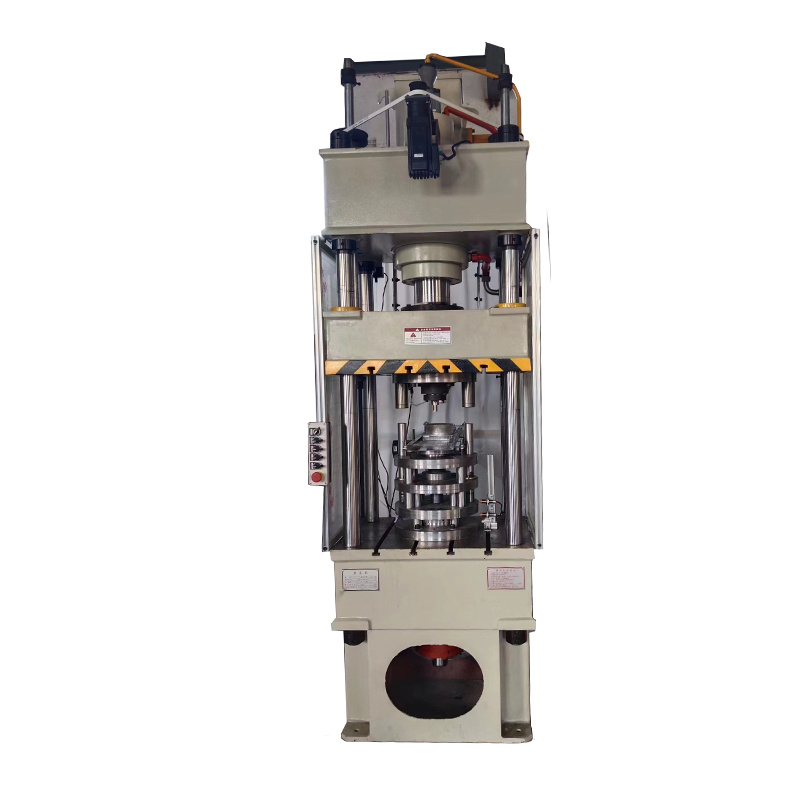

Hydraulic press

Hydraulic press

- Product Description

-

YD-120C automatic press instruction manual general type

Dear users:

Sincerely thank you for your trust in our company and use our products. Please keep the following precautions in mind during the use of this product:

1. Before operating the machine, please read the instruction manual carefully and follow it. Those who do not understand the structural performance and operating procedures of the machine are not allowed to start the machine and disassemble and repair it without authorization.

2. Empty top pressure test of hydraulic cylinder is strictly prohibited.

3, it is strictly prohibited to overload, over travel and more than the maximum eccentricity of use4. After the initial test run and oil change, the air in the system shall be drained after the test run.

5, please keep the oil clean.

6. The grounding of electrical equipment must be firm and reliable.

Non-professionals are not allowed to operate or adjust the machine, and are not allowed to disassemble or modify electrical lines and hydraulic pipes.

8. The power circuit of this machine adopts 380V three-phase four-wire system (or three-phase five-wire system with special requirements), and the electrical control cabinet is strictly prohibited from moving frequently.Purpose and characteristics of the machine

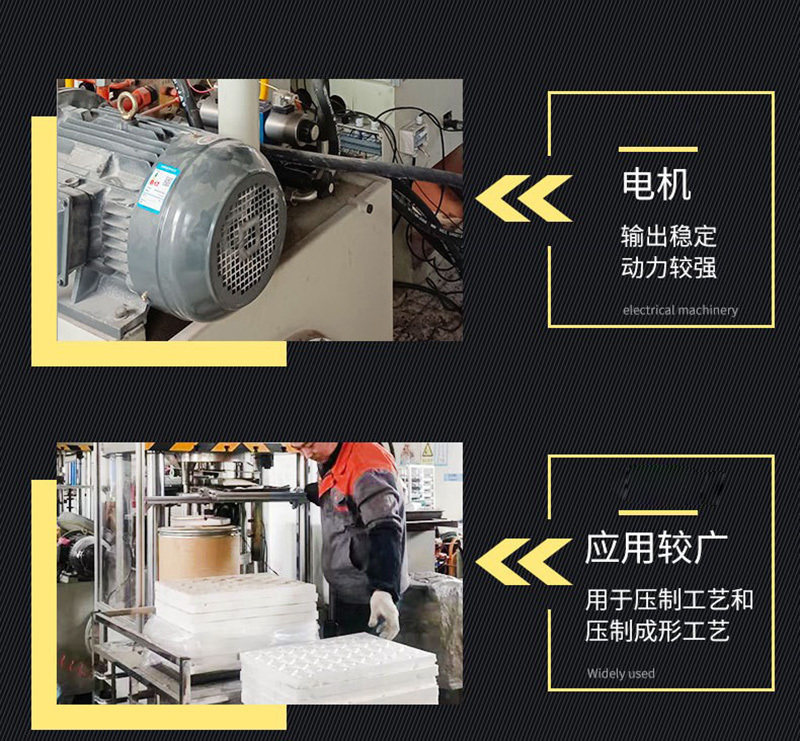

This machine is suitable for the pressing process of plastic materials, such as stamping, bending, flanging thin stretching, etc. It can also be engaged in correction, pressing, pressing and forming of plastic products and powder products.

The three-beam and four-column structure is optimized by computer and is economical and applicable. The hydraulic control system uses a plug-in integrated system. It has reliable action, long service life, small hydraulic impact, reduced connecting pipes and leakage points, reliable work, intuitive action and convenient maintenance. It adopts button centralized control, set adjustment (inching) and single (semi-automatic) two operation modes, which can realize two molding processes of fixed range and fixed pressure, it also has the performance of pressure holding delay and automatic return action, and the working pressure and stroke can be adjusted within the specified range according to the process requirements.

Main technical parameters

Name

Unit

Data

Remar

Pressure

Main cylinder Nominal Pressure

KN

1200

Ejecting Nominal Pressure

KN

/

Max.liquid working pressure

Mpa

25

Stroke itinerary

Slide stroke

mm

500

Ejecting stroke

mm

/

Opening Heigh

The max opening height

mm

900

The effective size o Worktable

Left to right

mm

700

Front to back

mm

620

Speed

Descending speed

Mm/s

80

Return speed

Mm/s

100

Machine total power

Machine total power

KW

7.5

Voltage

Machine need Voltage

V

380

Inner diameter of cylinde

Inner diameter of the main cylinde

mm

/

Weight

Machine total weight

Kg

/

YD32-200BK hydraulic press instructions

Dear users:

Welcome you to choose the four-column hydraulic press produced by our factory. Please read the instructions carefully before starting the machine. Only when you have a detailed understanding of the equipment can you use the equipment safely and skillfully.

In order to ensure the normal operation of the equipment and your safety, please remember the following instructions:

1. Ensure that the equipment is connected to the power supply and grounded correctly and reliably;

2. Please cut off the power supply during adjustment and maintenance;

3. It is strictly prohibited to test the pressure of hydraulic cylinder with empty top;

4, the initial pressure test is strictly prohibited overload use;

5. After the initial test run and oil change, the air in the system shall be drained after the test run;

6. Please keep the oil clean.1. safe operation must know

Operators must comply with safety rules.

2. Keep the environment around the machine clean and tidy.

3, the operator should wear the necessary labor protection supplies at work.

4, the operator must carefully read the instructions and other relevant information to ensure the correctness of the operation and production process.

5. The operator should memorize the position of the emergency stop button so that the button can be pressed quickly at any time.

6. The various handles and buttons of this machine are best operated independently by one person! If two or more people work together, the workers should keep in touch with each other and inform each other between starting new work (steps) to ensure personal safety.

7. Lubricating oil recommend use N46 engine oil.

8. Before starting the hydraulic press, ensure reliable clamping of the mold and workpiece, and the fastening wrench shall not be omitted on the work surface.

9. Only after the hydraulic press stops running can the mold and workpiece loading and unloading be carried out.

The hydraulic press should be reliably grounded, and reliable grounding can effectively prevent the danger of electric shock.Two safety guidelines

Note: The operator must read this manual in detail before using the machine bed, and guide the operation according to the contents of the manual.

The warning information and possible faults involved in this specification only include those situations that can be predicted, and do not include all possible situations.

1. Machine tool installation requirements

(1) In order to ensure the accuracy of the machine tool, the following conditions should be met when installing the machine tool:

A, use the altitude of not more than 1000m.

B, the use of ambient temperature changes with the season, generally should be 0-40 ℃.

C, the use of environmental relative humidity should generally be 40-90%.

D, the installation position to avoid direct sunlight or excessive vibration.

(2) Main power requirements:

a. Power supply voltage: AC380V; power supply frequency: 50HZ.

B. Voltage fluctuation: maximum ± 10%; Frequency fluctuation: maximum ± 1%.

2. Precautions before power-on

(1) Close the door of the electrical cabinet to prevent the entry of oil and iron dust.

(2) After power on, first turn on the main switch of the machine tool. When the power indicator of the machine tool is on, turn up the emergency stop button to operate the machine tool.

3. Precautions

(1) After the power is turned on, complete the corresponding work according to the daily inspection and maintenance items specified in the manual.

(2) The size and type of the selected mold should meet the processing requirements and meet the machine tool specifications to avoid damage to the use, so as not to prevent accidents.

(3) The installation of workpieces and molds should be firm and reliable.

(4) It is strictly prohibited to touch the mold and workpiece when the hydraulic press is working.

(5) Before operating the switch or button on the panel, confirm the operation diagram and the position of the button to prevent misoperation.

4. Main items in the maintenance process

(1) When a fault occurs, press the emergency stop button on the operation panel to stop the machine tool.

(2) When the machine does not work properly, check the relevant manuals and instructions to determine the correct measures to be taken.

(3) Before overhauling or replacing components, the power must be turned off.

(4) The parts (components) removed during maintenance should be replaced with the same new parts (components) in place, and may be fastened with screws of the original specifications.

(5) regularly check the cable, wire for damage, to prevent leakage or click.

(6) Maintenance in electrical box

a. Before opening the electrical box, disconnect the main switch.

B. After the main switch is disconnected, the main switch is still live. Therefore, maintenance personnel must pay special attention. Even service personnel must comply. If you need to open the electrical box door with electricity for maintenance, you should pay attention to safety, and it is strictly forbidden to touch any live objects in the box with your hands.

C, regularly check the outer surface of the electrical box, keep clean and clean.Three main technical parameters

1: Host:

(1) Loading height: 200mm

(2) Master cylinder: maximum nominal force 2000kN (adjustable)

Maximum return force 80kN (adjustable)

Maximum working stroke 600mm(3) EJECTION CYLINDER: MAXIMUM EJECTION (FLOATING POWER) 600kN (ADJUSTABLE)

Maximum return force (pull-down force) 15kN (adjustable)

Maximum working stroke 200mm

(4) Effective area of worktable: 800 × 800 mm × mm

(5) The host is a three-beam four-column structure

(6) Working frequency: 3-5 times/minute

(7) length * width * height: 1240mm × 960mm × 2800mm

2: hydraulic station

(1) The 40ml high-pressure plunger pump is used for oil supply, and the motor power is 7.5kW;

(2) The hydraulic system adopts 10-diameter high-quality solenoid valve and plate-type integrated oil system, which has a clean appearance and is easy to maintain;

(3) The oil circuit realizes the following actions:

A master cylinder action: divided into fast down, slow down pressing, return;

B lower cylinder action: it is divided into ejection and return;

c action of feeding stepping system: push forward, vibration feeding, backward;

(4) Fuel tank volume: ≥ 0.3m ³ (closed type);

(5) Centralized oil return, oil return line with cooler, and oil suction filter at oil inlet.

3: Mould base part

(1) Configure the next mold base;

(2) Maximum feeding height: 200mm;

4: electrical control system

(1) electrical control using PLC programmable controller touch screen control.

(2) The stroke position control adopts proximity sensor switch or pressure signal.

(3) The control time is: pressing time, feeding delay, small cylinder delay three groups.

(4) Feeding is a multi-segment adjustable speed CNC stepping feeding system.

(5) The knobs are centrally arranged on the front of the press for convenient operation, and the touch screen displays rich content

(6) Equipped with safety anti-pressure hand device.Overview of structure and use

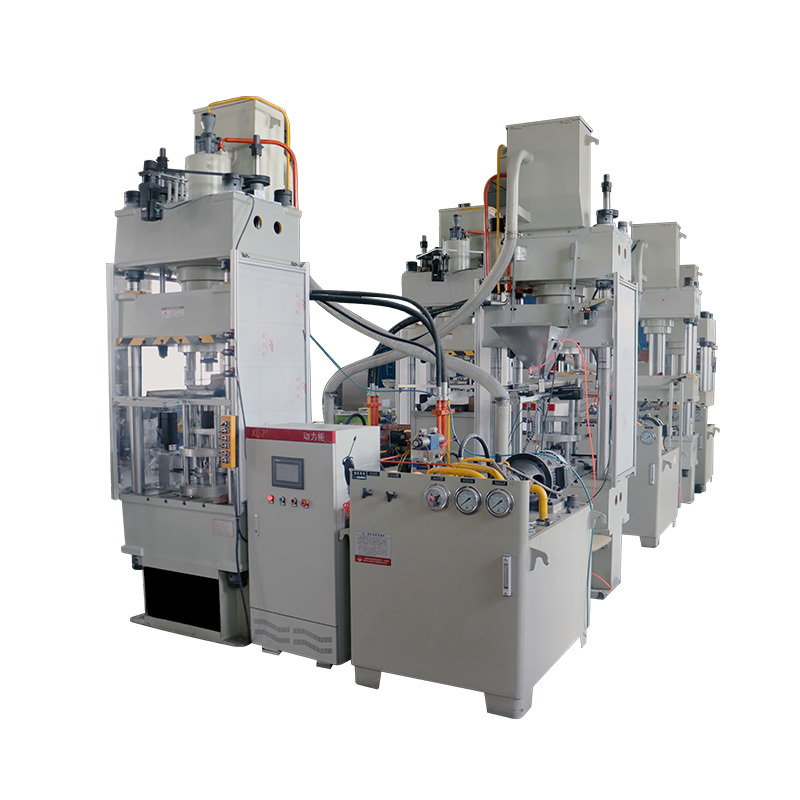

This machine is a four-column upper pressure hydraulic press, which is suitable for pressing phenolic plastic bakelite, rubber, stretching powder metallurgy, grinding wheel, recycled leather, bending, flanging, press-fitting, maintenance and other press-fitting forming processes.

The operation mode is inching and automatic, and the user can adjust the pressure according to the production process requirements within the nominal pressure range. It has the advantages of compact and reasonable structure, convenient operation and maintenance. The structure of the machine consists of two parts: the main part: the top frame is connected by four columns, and the oil cylinder is installed on the steel cap. The sliding beam is installed between the top of the machine and the working table, connected by a plunger with an upright post as the guide, and moves up and down together with the plunger. The parallelism between the sliding beam and the working table is adjusted by four nuts under the cylinder cap.

Hydraulic pump station part: the entire hydraulic control system consists of a high-pressure pump and control components, installed on the tank and the bottom plate. The hydraulic pump station is installed above the main engine, and the high-pressure oil pipe is connected with the main cylinder and the lower top cylinder. By adjusting the remote pressure regulating valve to change the value of the pressure gauge, so as to adjust the actual working pressure of the press, the handle should be slowly turned to prevent damage to the pressure system components.

Working pressure calculation: working pressure of press (ton) = R×R×∏ × pressure gauge valueComparison table of nominal pressure and system pressure:

tonnage

System pressure100T

150T

200T

250T

315T

400T

500T

1000T

Cylinder diameter (mm)

220

250

300

320

360

450

480

700

Maximum system pressure (MPa)

27

31.5

29

31.5

31

26

28

26

1MPa

3.8T

4.9T

7.06T

8.03T

10.17T

15.9T

18.09T

38.5T

Installation, Commissioning and Precautions

The main engine and pump station of this machine are shipped separately, and the instructions, product certificate, packing list and accessories are randomly delivered. After the machine to the factory, installation and lifting should pay attention to the method and safety.

The machine is installed on the specified concrete foundation, correct the horizontal installation of anchor screws, connect the oil cylinder with the oil pipe of the control part, and then adjust the accuracy of the base and sliding beam of the main machine.

For transportation reasons, check the fastening parts for looseness.

Fill the oil tank with filtered 46~68# hydraulic oil (add it to the height of level gauge 80)

The lower body of the high pressure pump is filled with 46~68# hydraulic oil

Check whether the electrical equipment is in good condition and whether the wire connector is loose, and then connect the power supply.

Commissioning:

1) The test driver must first understand the principle, structure and performance of the machine, and test it in accordance with the instruction manual.

2) After the power is turned on, start the motor and observe whether the rotation direction is correct.

3) Start the motor, no-load test run, press the button sliding beam to make up and down full stroke several times (each time shall not exceed 300mm) to exhaust the air of the system.

4) The load test shall be increased step by step. Before the pressure test, loosen the handwheel of the overflow valve counterclockwise. Then, between the machine base and the sliding beam, the normal area shall be 400 × 400mm, the height shall be greater than or equal to 300mm, the two sides shall be parallel, and there shall be metal anvils sufficient to bear the pressure. After normal operation, the pressure shall be gradually increased. After each pressure holding, check shall be, after the machine is adjusted normally, it can be put into production.Note:

1. Electrical appliances shall be grounded.

2. The machine is not allowed to correct the mold during operation.

3. The minimum area of the mold during the operation of the machine shall not be less than 400 × 400mm. For the small area of the mold, the upper and lower pads have sufficient pressure area, and the height shall be higher than the minimum spacing between the press base and the sliding beam.

4. The oil is 46~68# mechanical oil, and it is used after being filtered by 80~100 mesh copper wire. The first oil change time should not exceed two months, and the oil should be changed every six months or so.

5, the press shall not overload load, liquid pressure

6, in the test run and production if found abnormal should immediately stop inspection.

7. keep pressure for 10 minutes to allow 2.5mpa.

8. When working, the eccentricity of the workpiece placement position is not more than 20mm.

Key words:

Message consultation

Related Products