Product classification

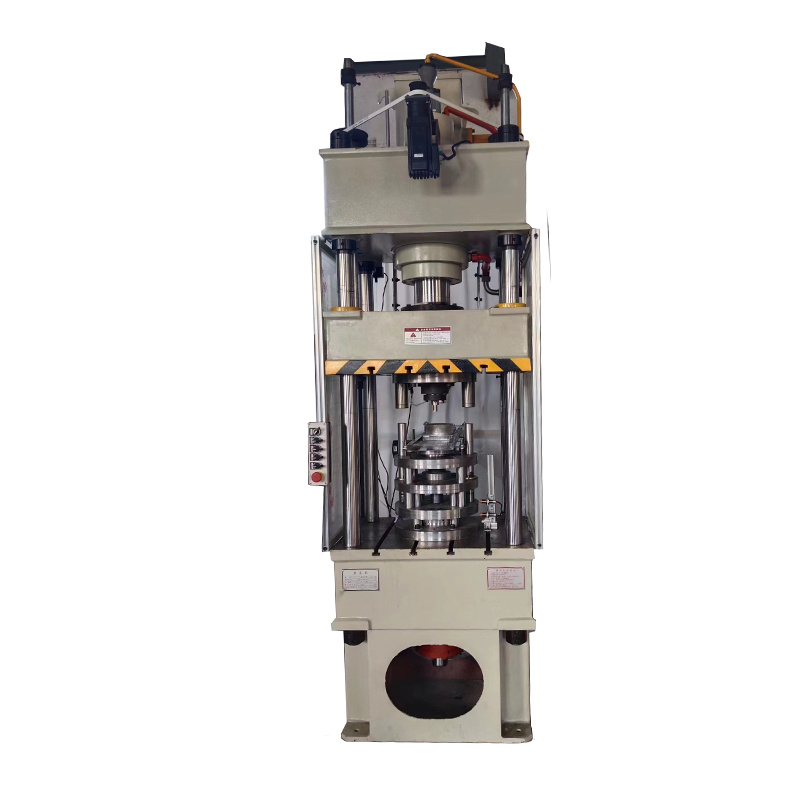

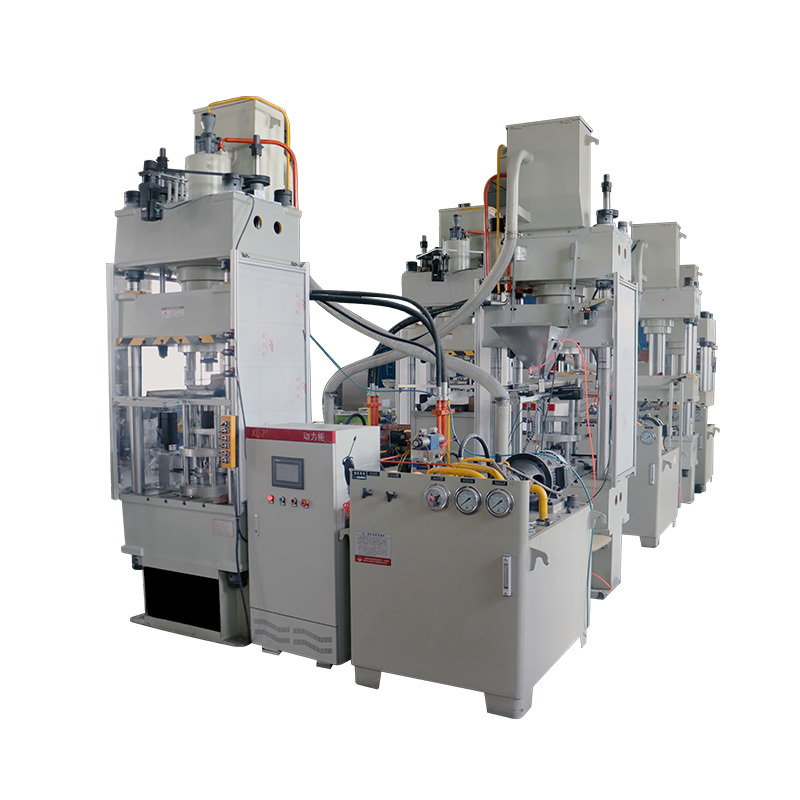

Spot welding machine

The design is novel, easy to use, safe and reliable in performance, especially its full-mode capacitive impulse discharge mode ", so the solder joint has no spot marks. It is not only widely used in small zero connection of welding stainless steel wires, stainless steel sheets and other materials of different specifications in the industries of instruments and meters. High efficiency and energy saving, more than 1/3 power saving than ordinary AC point machine.

- Product Description

-

Product Features

The design is novel, easy to use, safe and reliable in performance, especially its full-mode capacitive impulse discharge mode ", so the solder joint has no spot marks. It is not only widely used in small zero connection of welding stainless steel wires, stainless steel sheets and other materials of different specifications in the industries of instruments and meters. High efficiency and energy saving, more than 1/3 power saving than ordinary AC point machine.

Principle of spot welding (resistance welding)

When a huge electric current passes through the workpiece to be welded in an instant, the temperature on the workpiece to be welded gradually reaches or even exceeds the melting point after sufficient heat is generated on the surface of the workpiece to be welded. At this time, when the workpiece to be welded is also properly fixed (welding pressure), the workpiece to be welded will be mixed, and after the formation of a combined solidification body (solder joint).Q = I2Rt

Q = Heat from welding

I = welding current

R = Contact resistance

t = welding time

In the process of spot welding, the factors affecting welding:

In the spot welding process, in addition to the characteristics of the welded workpiece itself, the factors that usually affect the welding are welding current, welding time, contact resistance, welding pressure, electrode and other spot welding process parameters are often selected according to the material and thickness of the workpiece, first determine the shape and size of the electrode end face. Secondly, the electrode pressure and welding time are initially selected, and then the welding current is adjusted to weld the sample with different current. After checking that the nugget diameter meets the requirements, the electrode pressure, welding time and current are adjusted within an appropriate range to weld the sample. And inspection, until the quality of the solder joint fully meets the requirements specified in the technical conditions. The most commonly used method of testing the sample is the tear method. The sign of high-quality solder joints is that there is a round hole on one piece of the tear sample and a round boss on the other piece. Thick plates or quenched materials sometimes cannot tear out round holes and bosses, but the diameter of the nugget can be judged by shearing the fracture. When necessary, low-power measurement, tensile test and X-ray inspection are also required to determine the penetration rate, shear strength and the presence of shrinkage holes and cracks. When selecting the process parameters with the sample, the differences between the sample and the workpiece in the shunt, the influence of ferromagnetic substances, and the assembly gap should be fully considered, and adjusted appropriately. The power supply of the multi-function welding machine compresses the two weldments to be connected during operation, and is directly controlled and triggered by the CPU after being energized, which releases a large amount of energy in an instant, causing the two contact surfaces to generate a large amount of heat and quickly heat to its melting point temperature. In this way, the weldments are tightly welded together.

1. multi-function welding machine

The design is novel, easy to use, safe and reliable performance, especially its full simulation "capacitor punch discharge mode" so no spot, it is not only widely used in electrical appliances, instruments and other industries welding different specifications of stainless steel wire, stainless steel sheet and other materials of small parts welding.

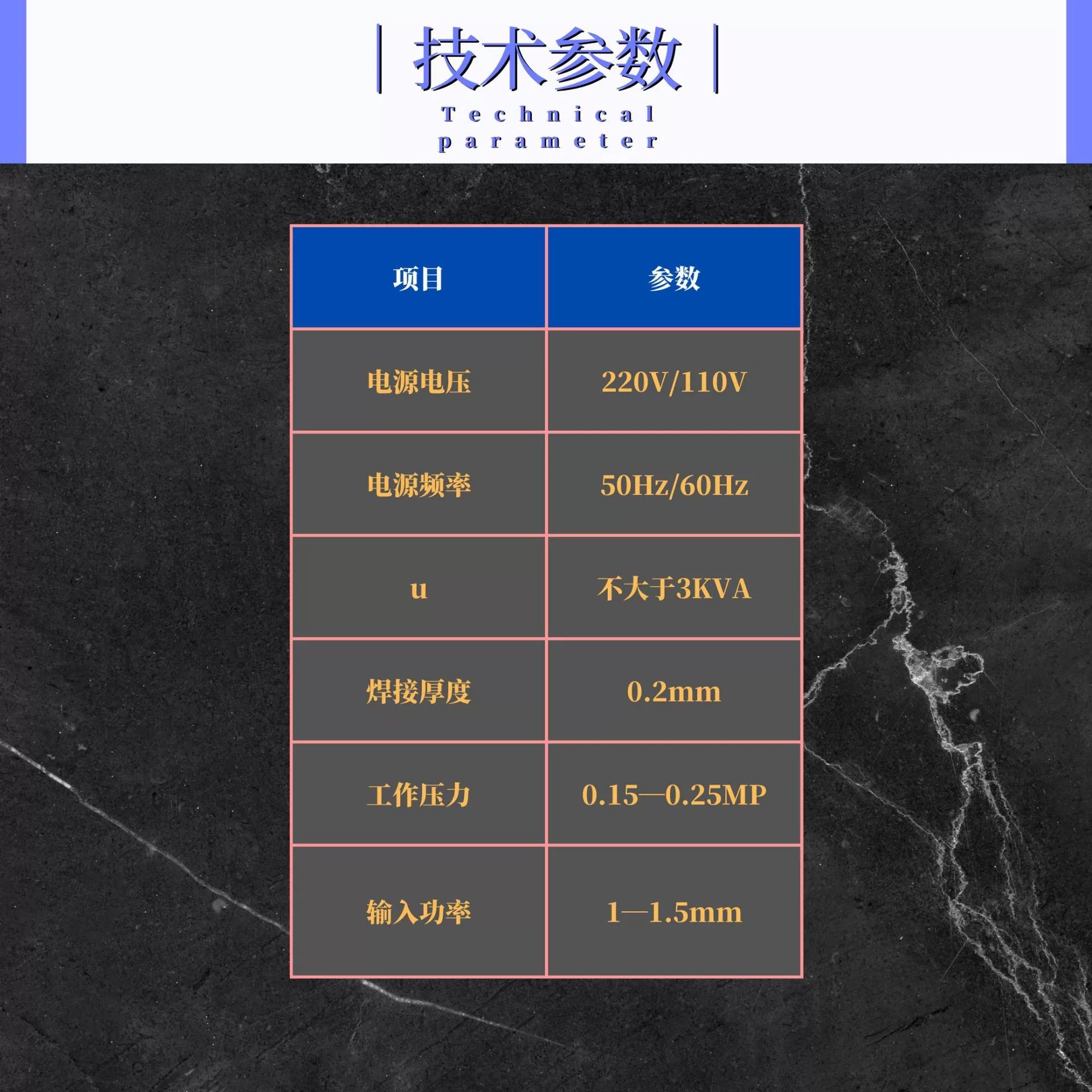

Main technical performance of 2.

Power supply voltage: 220V ± 10% /110V ± 10%

Power frequency: 50Hz/60Hz

Input power: not more than 3KVA

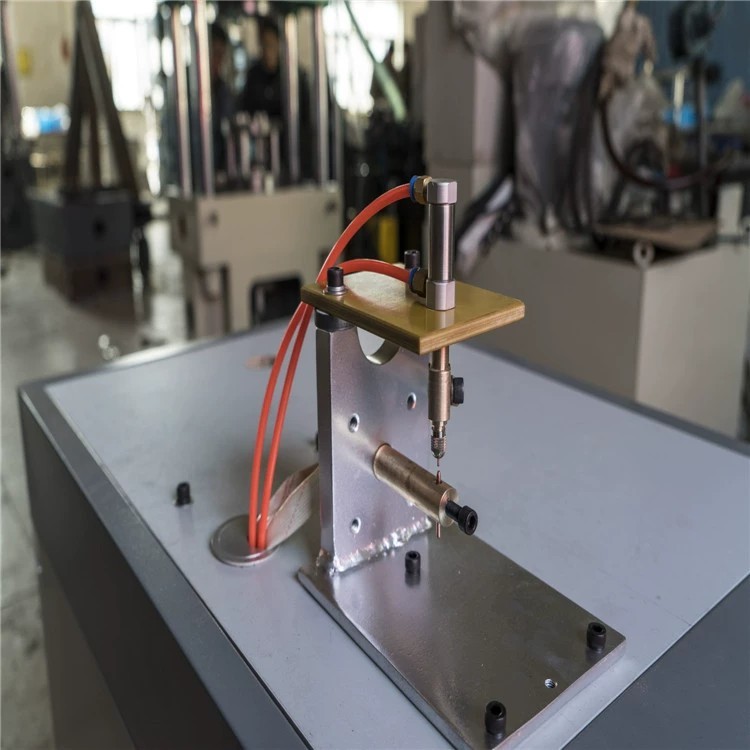

3. method of use

1. Check the electrode before welding. If it is found to be oxidized, sand the welding point with fine sandpaper.

2. Turn on the power, turn on the power switch, and the instrument is in the latest working state. The user can change the current again according to the work needs, and the foot switch starts to work with a long step of 1 second. The user must use the instrument in the corresponding working state to avoid damage to the instrument by misoperation.

Welding thickness: 0.2mm

Working pressure: 0.15-0.25Mp

Nugget diameter: 1-1.5mm

3. Spot welding:

During spot welding, adjust the button according to the thickness of the spot welding workpiece to adjust the energy display to the appropriate position. Hold the workpiece in both hands and align it. Place the workpiece to be welded between the upper and lower electrodes, that is, step on the foot switch to press the workpiece for welding. After the welding is completed, take down the workpiece. If continuous welding is required, press the foot switch continuously (the interval between continuous welding is about 0.3-0.5 seconds).

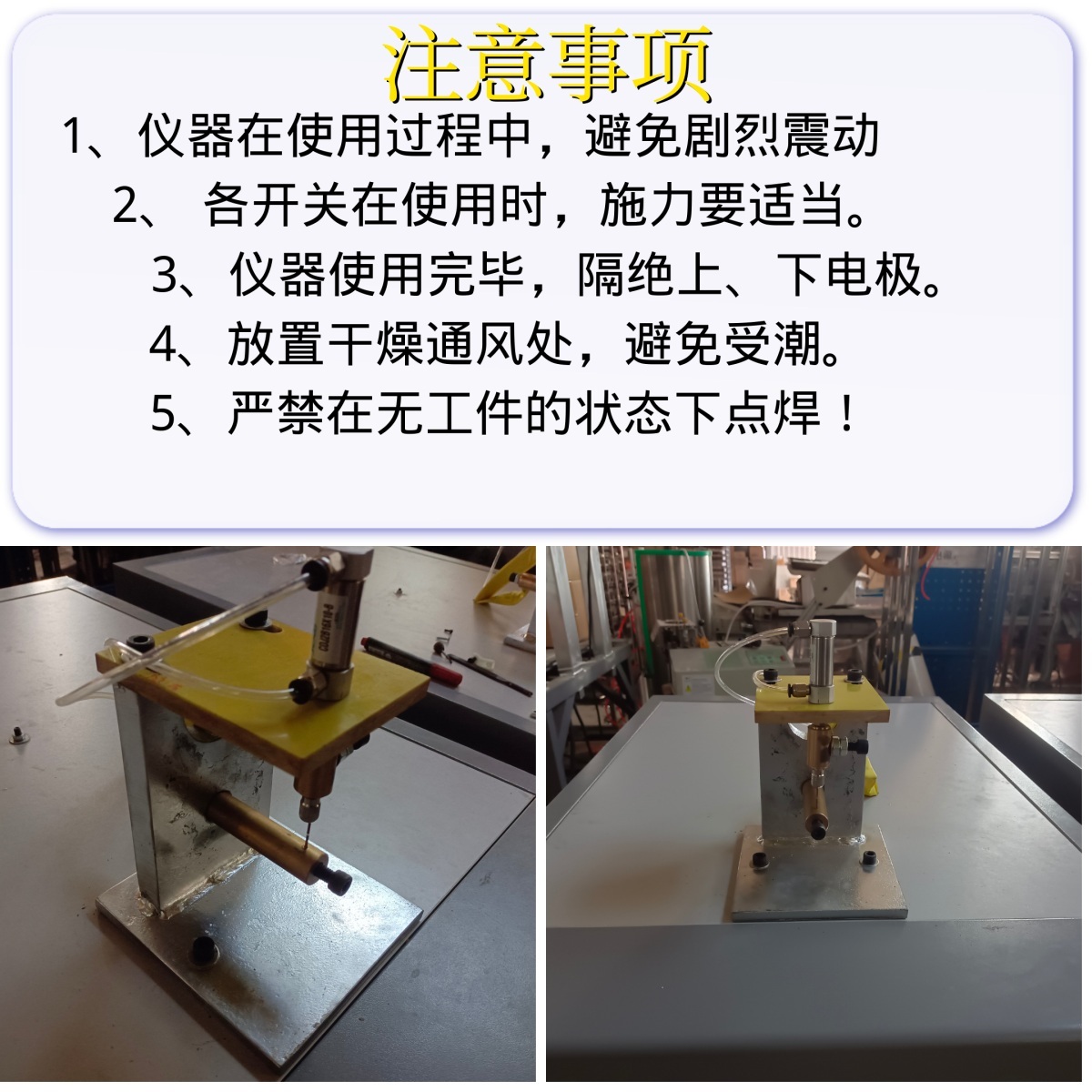

4. considerations

1. Avoid violent vibration during the use of the instrument.

2, each switch in use, the force should be appropriate.

3. After the instrument is used, isolate the upper and lower electrodes.

4. Place in a dry and ventilated place to avoid moisture.

5, it is strictly prohibited in the state of no workpiece spot welding!

5. general failure causes and maintenance

1. The power supply of the instrument does not work, the fuse is blown, and the fuse is replaced.

2. Do not discharge when working, check the foot switch, wire and electrode.

3, the cylinder does not go down, check the air source and pressure reducing valve.

6. multi-function welding machine components (each equipment should be equipped with)

1. Host 1

2.2 3mm electrodes

3.1 power cord

4. Instruction 1 copy

5.1 fuse tube (10A glass tube)

6. Foot control switch 1The equipment is updated relatively quickly. If there is any discrepancy with the instructions, please consult the manufacturer.

Contact Phone:15666852878

Key words:

Message consultation

Related Products