Product classification

Cleaning machine

Ultrasonic cleaning is the use of ultrasonic in the liquid in the socialization of the role, acceleration and direct flow of liquid and dirt on the role of direct and indirect, so that the dirt layer is dispersed, emulsified, stripped to achieve the purpose of cleaning.

- Product Description

-

Ultrasonic cleaning machine parameters

Dimensions: 4000*800*800mm

Number of vibrators: 45

Heating power: 3Kw * 3

Ultrasonic power: 3Kw

The equipment is updated relatively quickly. If there is any discrepancy with the instructions, please consult the manufacturer.

Principle of 1. ultrasonic cleaning machine

Ultrasonic cleaning is the use of ultrasonic in the liquid in the socialization of the role, acceleration and direct flow of liquid and dirt on the role of direct and indirect, so that the dirt layer is dispersed, emulsified, stripped to achieve the purpose of cleaning.

The ultrasonic transducer converts a high-frequency oscillating electrical signal into a high-frequency mechanical oscillation, which is radiated in the cleaning fluid in the form of a longitudinal wave. During the half-wave of the radiation wave expansion, the compactness of the cleaning liquid breaks down and numerous bubbles with a diameter of 50-500 μm are formed. This bubble is filled with solution vapor. During the half-wave of compression, the bubble closes rapidly, resulting in a local hydraulic impact of hundreds of Mpa. This phenomenon is known as the "cavitation" effect. Under the continuous action of the "cavitation" effect, the dirt on the surface of the workpiece or the hidden place is burst and peeled off. At the same time, under the action of ultrasound, the penetration of the cleaning liquid is strengthened; the pulsating stirring is intensified; the dissolution, dispersion and emulsification are accelerated; thus the workpiece is thoroughly cleaned.

Composition of 2. ultrasonic cleaning machine

The ultra-wave cleaning machine is mainly composed of two parts: ultrasonic cleaning tank and ultrasonic generator. The ultrasonic cleaning tank is made of high-quality stainless steel with strong elasticity and corrosion resistance, and the ultrasonic transducer vibrator is installed at the bottom; the ultrasonic generator generates high frequency and high voltage, which is transmitted to the transducer through the cable connection line, and the transducer and the vibration plate together Generate high frequency resonance, so that the solvent in the cleaning tank is washed by ultrasonic action to clean the dirt.

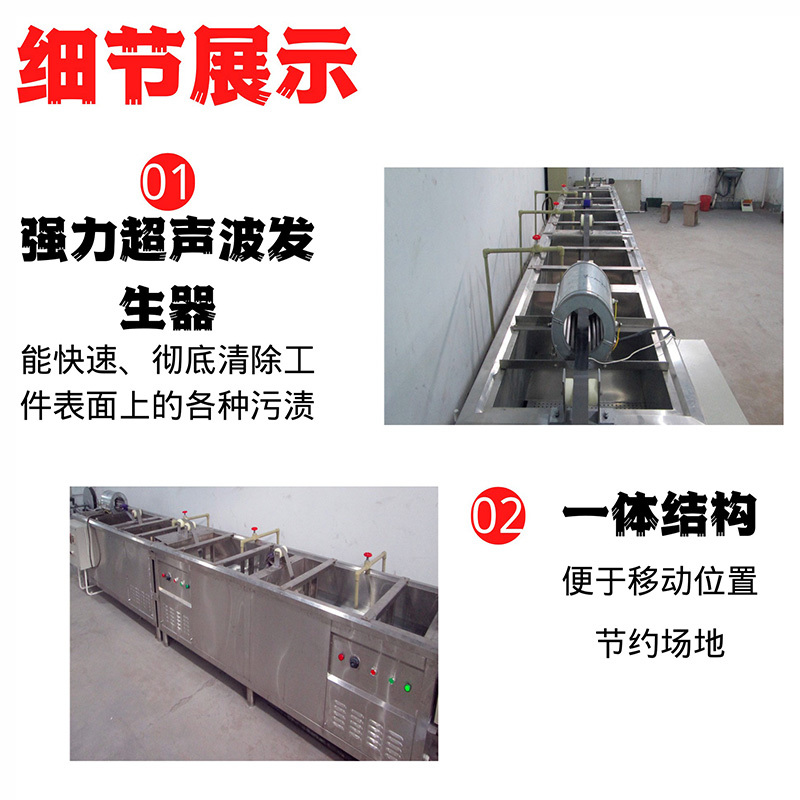

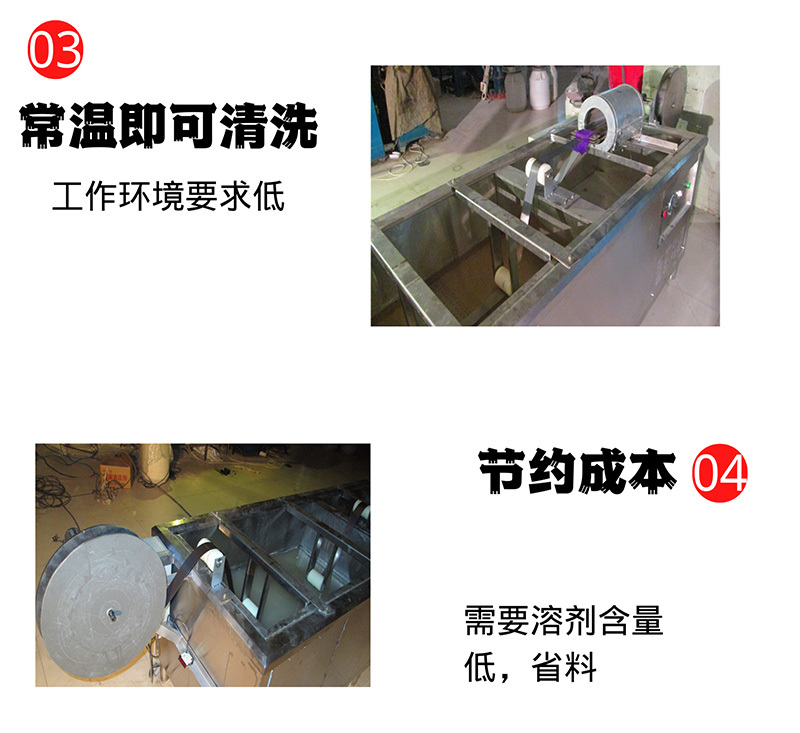

What are the characteristics of 3. ultrasonic cleaning machine

Compared with various chemical, physical, electrochemical and physicochemical cleaning methods, ultrasonic cleaning has the following unique advantages:

Can quickly and thoroughly remove all kinds of dirt on the surface of the workpiece. No damage to the surface of the workpiece. Various cleaning agents can be used. Cleaning can be carried out at room temperature or appropriate heating (about 60 degrees C). The integrated structure of the whole machine is easy to move. Save solvents, cleaning paper, energy, work space and labor.

4. how to use ultrasonic cleaning machine

The use of ultrasonic cleaning machine should be strictly in accordance with the following requirements of sub-step operation.

(1) Connect the power cable and grounding wire;

(2) Pour clean cleaning liquid into the cleaning tank (the amount of cleaning liquid poured into the cleaning object, the position of the liquid level is about the 2/3 of the whole is better); Ultrasonic cleaning machine is strictly prohibited in the tank when there is no water or solvent, do not start, resulting in empty vibration, resulting in vibration head scrap or damage.

(3) Put the object to be cleaned into the cleaning tank;

(4) Open the heating control temperature at 50-60 ℃ and start the inverter to work. Turn off all power after work. (5) The bottom of the cleaning tank shall be cleaned every day without sundries or dirt. It is forbidden to hit the bottom of the cleaning cylinder with heavy objects (iron parts) to avoid damage to the energy converter chip.

(6) The drain valve must drain water when the water temperature is low to prevent scalding personnel and the valve. Ultrasonic cleaning iron belt 4 rolls once a day 2 rolls.

Ultrasonic cleaning machine parameters

Overall dimensions: 4000*800*800mm oscillator number: 45

Heating power: 3 kW * 3 ultrasonic power: 3 kW

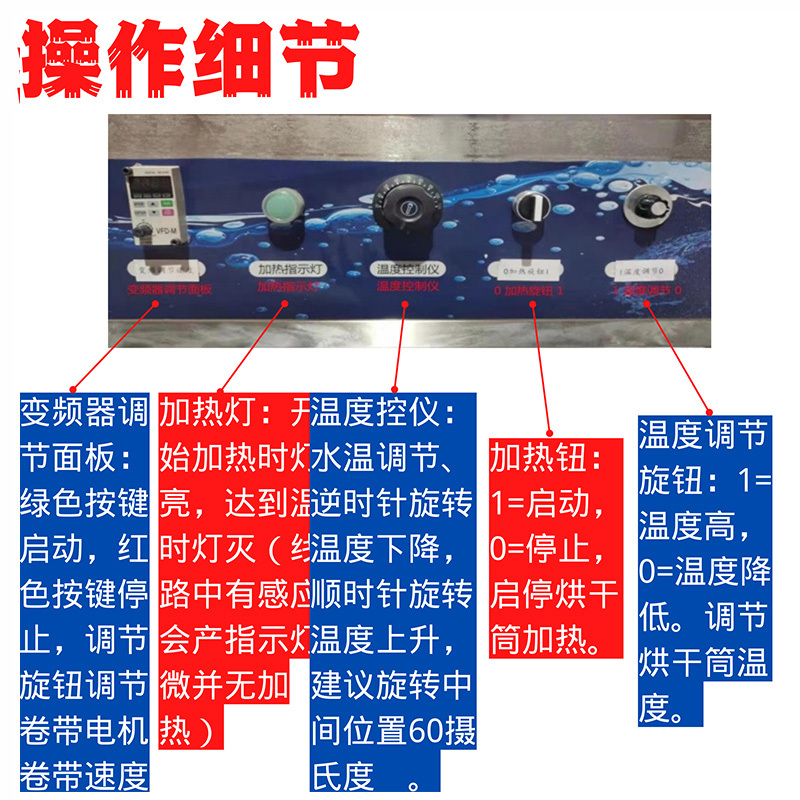

Inverter adjustment panel: green button to start, red button to stop, adjustment knob to adjust the winding speed of the winding motor.

Heating indicator light: the light is on when heating starts, and the light is off when the temperature is reached (induction in the line will cause the indicator light to be slightly bright, and there is no heating).

Temperature controller: water temperature adjustment, counterclockwise rotation temperature drop, clockwise rotation temperature rise, it is recommended to rotate the middle position 60 ℃.

Heating knob: 1 = start, 0 = stop, start and stop drying cylinder heating.

Temperature adjustment knob: 1 = temperature increase, 0 = temperature decrease. Adjust the drying cylinder temperature.

The equipment is updated relatively quickly. If there is any discrepancy with the instructions, please consult the manufacturer.

Contact Phone:15666852878

Key words:

Message consultation

Related Products