Product classification

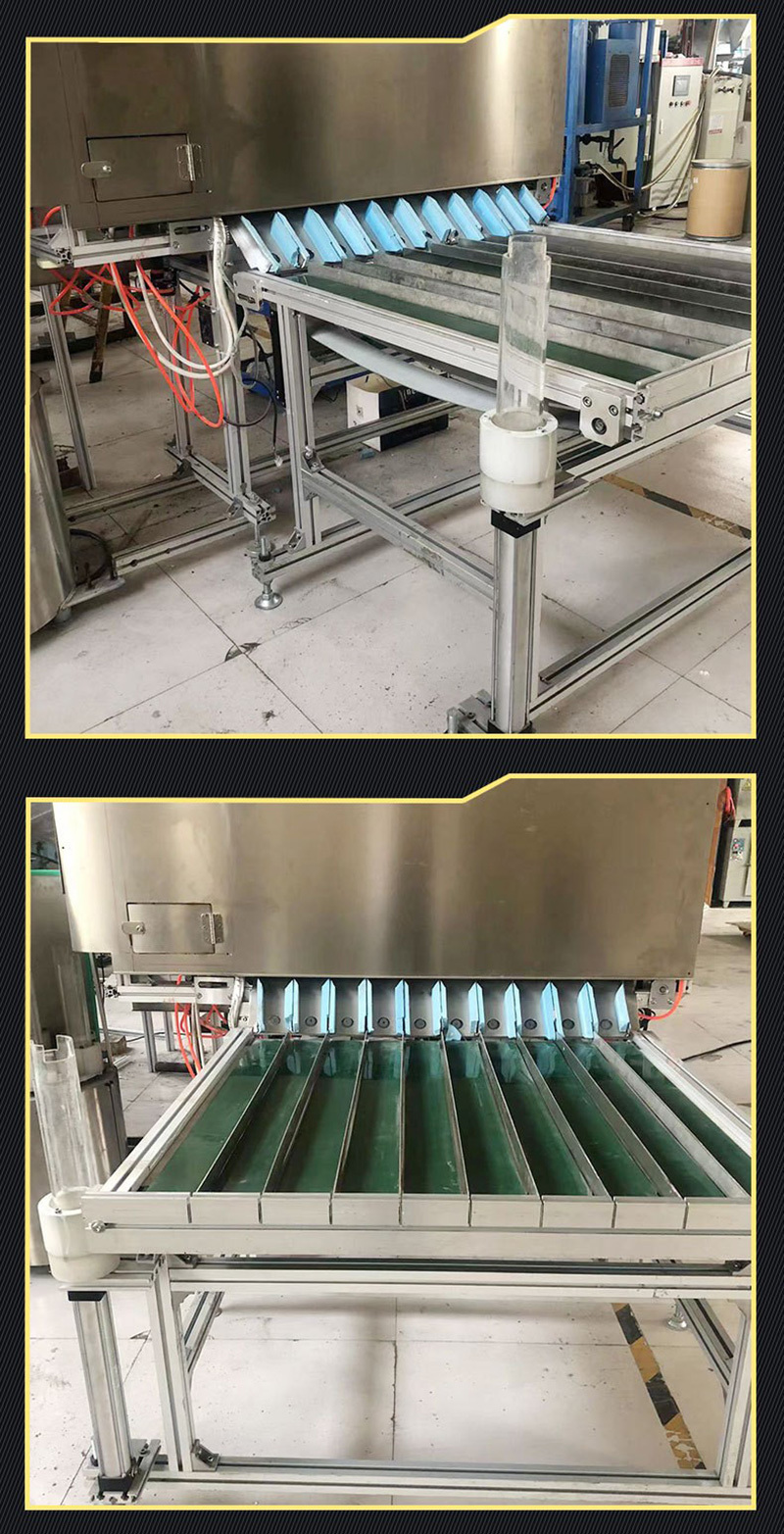

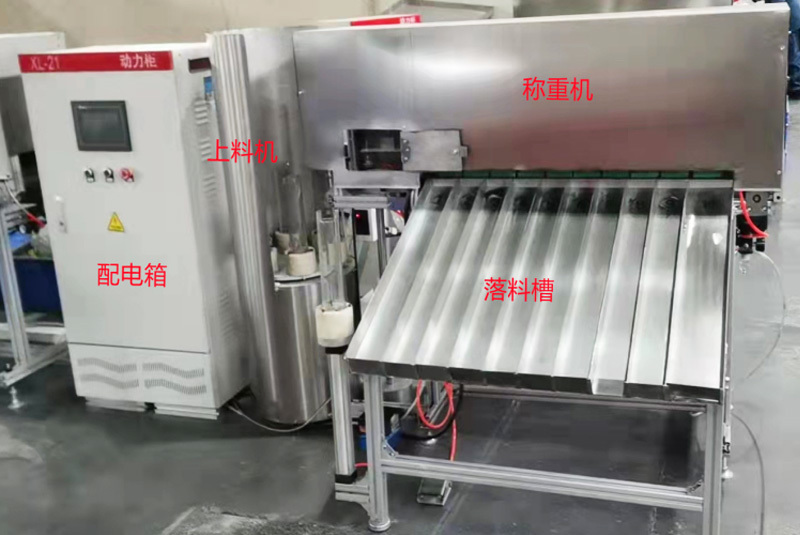

Weight sorting machine 2

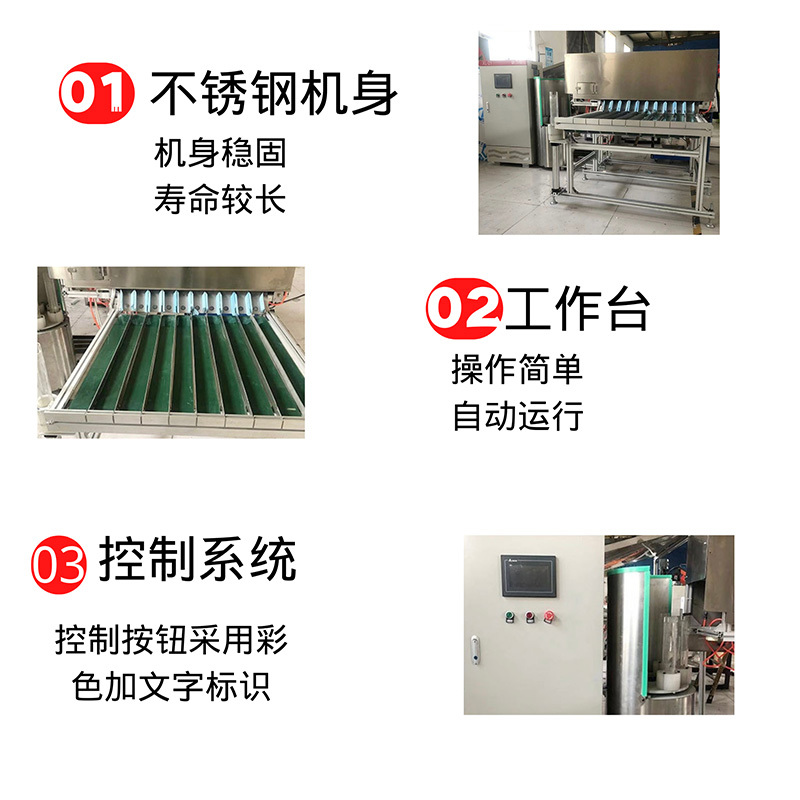

One. Automatic operation of equipment (1) Turn on the power and click back to the zero position on the display. (2) Click the semi-automatic button on the display screen of the feeder, and then press the green button to start the feeder. (3) Click on the automatic manual on the weighing machine display.

- Product Description

-

One. Automatic operation of equipment

(1) Turn on the power and click back to the zero position on the display.

(2) Click the semi-automatic button on the display screen of the feeder, and then press the green button to start the feeder.

(3) Click on the automatic manual on the weighing machine display.II. Precautions

(1) Before the feeding machine starts automatically, check whether the push rod motor returns to the lowest end, and click the status monitor to check whether the ejection return is in place. If not, it cannot run automatically.

(2) Check whether the weighing scale returns to zero. If it does not return to zero, it will stay at the upper material level and cannot run automatically.

(3) If the suction cup of the manipulator does not suck to the workpiece of the feeding machine and there is no workpiece on the workpiece, it will stay at the lower material level and not work.

(4) If the manipulator does not suck the workpiece on the weighing plate, the manipulator stays in the blanking waiting position, and if the weighing does not return to zero, it will not work.

Three. Weight setting

(1) Click on the weight setting on the display of the weighing machine, there are 1-3 formulas, and set the weight according to the requirements.

Four. Parameter setting (four positions of manipulator from left to right)

(1) Feeding speed/position,

(2) Waiting position for loading,

(3) blanking waiting position,

(4) blanking speed/position,

Five. Time Setting

(1) The weight of each gear is getting longer and longer from near to far, and the longest does not exceed the maximum value that can be set.

(2) The delay of material grasping waiting and material grasping is mainly to extend the delay of 0.1 seconds on the premise of ensuring reliable material grasping.

(3) The speed value on this interface is the speed of manual operation of the manipulator.

VI. Fault handling

1, boot back to zero does not act:

Processing method:(1) If the emergency stop switch is not opened, open the emergency stop switch.

(2) The manipulator is too low at the feeding position, and the power failure turns the manipulator to the feeding position.

2. Does not work in automatic state

Processing method:(1) If the scale is not reset to zero, press the zero button on the scale panel.

(2) If the manipulator does not catch the product and makes it vacant, click "Auto, Manual" on the control panel to work again.

3. The feeding or blanking position affects the accuracy or inaccuracy of the weighing, and the blanking position is adjusted. Mechanical hand pressure weighing, adjust the feeding position.

The equipment is updated relatively quickly. If there is any discrepancy with the instructions, please consult the manufacturer.Contact Phone: 15666852878

Key words:

Message consultation

Related Products