Classification of diamond powder

Release time:

2023-05-12

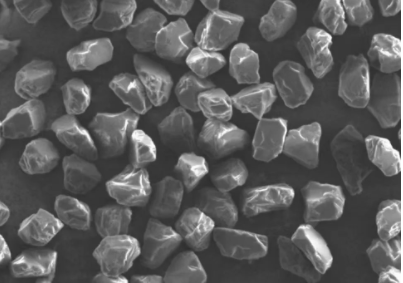

DiamondMicro-powderAfter the completion of the ball milling crushing, shaping and coarse purification process, there is a very important process, that is, the product size.GradingThe main purpose of the treatment is to require the particle size distribution to be as concentrated as possible and to completely eliminate oversize particles. Duediamond powderThe particles are too fine, the traditional screen classification can not achieve accurate classification, the selection of scientific, efficient and precise classification method is particularly important.

With the continuous expansion of the application field of diamond micropowder and the gradual improvement of the quality requirements of the market, the classification methods commonly used in diamond micropowder enterprises at this stage are: natural sedimentation method, centrifugal method, overflow method, screening method, hydrocyclone method, etc.

01. Natural sedimentation classification and centrifugal classification

Diamond particles in the same proportion, different particle size in the water with different sedimentation rate, natural sedimentation method is based on this principle, control of sedimentation height and sedimentation time of particle size classification. The particles are subjected to three forces in the liquid, namely the gravity generated by the inherent mass of the particles, the buoyancy of the liquid and the resistance of the medium to the particles. The particle settling velocity is related to the contact area between the particles and the medium, the viscosity of the liquid, and the frictional resistance of the particles in the medium.

The principle of centrifugal classification is the same as that of natural sedimentation classification. The difference is that the centrifugal method uses the centrifugal force generated by the centrifuge instead of gravity to classify the diamond micropowder products.

For coarse particles, due to the heavy particles and short sedimentation time, the natural sedimentation method can lengthen the sedimentation distance of particles with similar particle size, which is conducive to the fine classification of diamond powder products with similar specifications. However, for finer particles, due to the small weight of the particles, the speed of free settlement in the gravity field is very slow, and then the use of natural settlement method will greatly extend the production cycle, taking up a large number of classification containers and sites, ultrafine particles even due to Brownian motion and interference between particles can not be effectively classified. In the centrifugal force field, the centripetal acceleration far exceeds the acceleration of gravity, so that the speed of the movement of micro-powder particles is greatly increased, thus speeding up the classification speed. Therefore, many diamond powder production enterprises are the use of natural sedimentation method and centrifugal method of combining the production of fine to coarse full specification powder.

Natural sedimentation classification is the most basic diamond powder production method, the process is simple, product quality is relatively stable. However, it has the disadvantage of taking up more labor and having a longer production cycle for fine-grained products. The classification efficiency of centrifugal method for finer-grained products is much higher than that of natural sedimentation method, but the equipment investment is large, and the requirements for personnel operation are higher.

With the continuous expansion of the application field of diamond micropowder and the gradual improvement of the quality requirements of the market, the classification methods commonly used in diamond micropowder enterprises at this stage are: natural sedimentation method, centrifugal method, overflow method, screening method, hydrocyclone method, etc.

01. Natural sedimentation classification and centrifugal classification

Diamond particles in the same proportion, different particle size in the water with different sedimentation rate, natural sedimentation method is based on this principle, control of sedimentation height and sedimentation time of particle size classification. The particles are subjected to three forces in the liquid, namely the gravity generated by the inherent mass of the particles, the buoyancy of the liquid and the resistance of the medium to the particles. The particle settling velocity is related to the contact area between the particles and the medium, the viscosity of the liquid, and the frictional resistance of the particles in the medium.

The principle of centrifugal classification is the same as that of natural sedimentation classification. The difference is that the centrifugal method uses the centrifugal force generated by the centrifuge instead of gravity to classify the diamond micropowder products.

For coarse particles, due to the heavy particles and short sedimentation time, the natural sedimentation method can lengthen the sedimentation distance of particles with similar particle size, which is conducive to the fine classification of diamond powder products with similar specifications. However, for finer particles, due to the small weight of the particles, the speed of free settlement in the gravity field is very slow, and then the use of natural settlement method will greatly extend the production cycle, taking up a large number of classification containers and sites, ultrafine particles even due to Brownian motion and interference between particles can not be effectively classified. In the centrifugal force field, the centripetal acceleration far exceeds the acceleration of gravity, so that the speed of the movement of micro-powder particles is greatly increased, thus speeding up the classification speed. Therefore, many diamond powder production enterprises are the use of natural sedimentation method and centrifugal method of combining the production of fine to coarse full specification powder.

Natural sedimentation classification is the most basic diamond powder production method, the process is simple, product quality is relatively stable. However, it has the disadvantage of taking up more labor and having a longer production cycle for fine-grained products. The classification efficiency of centrifugal method for finer-grained products is much higher than that of natural sedimentation method, but the equipment investment is large, and the requirements for personnel operation are higher.

03. Classification by hydrocyclone method

The hydrocyclone method uses the principle of centrifugal sedimentation to accelerate the separation of coarse and fine particles through the high-speed rotation of the slurry in the hydrocyclone. As a mature technology, this process is widely used in coarse classification and product dehydration in various fields. Its main features are fast speed, simple operation, good repeatability, continuous feeding, in addition to 2 microns to fine particles of the whole series of diamond powder classification are effective. However, there is also a disadvantage of poor classification accuracy. As a method of coarse classification, it can greatly improve the production efficiency by combining with the natural sedimentation method and centrifugal method in the later stage.

Because each method has its inherent characteristics, the actual production, according to their own actual situation of flexible selection, can use a method of diamond powder product classification, can also use two or more methods of combining the product classification.

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution