Ultra-precision polishing of precision instruments for the use of nanodiamonds

Release time:

2023-06-23

Ultra-precision polishing of precision instruments for the use of nanodiamonds

We add nano-diamond to the medium to make nano-diamond polishing liquid, which is now mainly divided into aqueous polishing liquid and oily polishing liquid.

Because the nano-diamond polishing liquid nano-diamond particles ultra-fine ultra-hard, with it can remove the material surface of the small uneven, polished material surface roughness can be reduced to nano-level, so that the material surface finish is very high. At present, nano-diamond polishing liquid can be used in semiconductor silicon wafer polishing, computer head polishing, precision ceramic processing, gem polishing, optical glass polishing and other fields. Nowadays, due to the development of computers, people's requirements for computer storage capacity continue to increase, which makes us want to manufacture larger disks. In recent years, the storage capacity of computer disks has been increasing, but with the increase of storage capacity, the problem is that the gap between the disk and the head is getting smaller and smaller, approaching 10nm. The surface roughness, scratches and impurity particles of the head and the disk will cause damage to the computer disk. As the distance between the disk and the head has reached the nanometer level, the micron-level polishing liquid has not reached the polishing requirements, therefore, only nano-scale diamond polishing liquid can meet this demand. We used nano-diamond polishing liquid to polish the computer magnetic head, and found that the surface smoothness of the magnetic head was greatly improved after polishing. The measured surface roughness at this time was 0.09~0.40nm, while the surface roughness of the magnetic head was 0.45~0.80nm after polishing with ordinary polishing liquid. Compared with nano-diamond polishing liquid, the effect of nano-diamond polishing liquid is much better, thus the quality of the computer magnetic head is also improved, and we can produce more precision, A computer disk with a larger storage capacity. It is worth noting that when polishing, because the computer and other electronic products most avoid corrosion, so be sure to control the pH of the polishing liquid, the study found that the PH value of the polishing liquid is more appropriate to control between 6.5 and 8. Since the content of anions Cl-and SO2-will determine the pH of the polishing solution, the content of Cl-and SO2-should be controlled when preparing the polishing solution for computer head polishing, and the PH value should be observed at the same time.

Nowadays, due to the development of computers, people's requirements for computer storage capacity continue to increase, which makes us want to manufacture larger disks. In recent years, the storage capacity of computer disks has been increasing, but with the increase of storage capacity, the problem is that the gap between the disk and the head is getting smaller and smaller, approaching 10nm. The surface roughness, scratches and impurity particles of the head and the disk will cause damage to the computer disk. As the distance between the disk and the head has reached the nanometer level, the micron-level polishing liquid has not reached the polishing requirements, therefore, only nano-scale diamond polishing liquid can meet this demand. We used nano-diamond polishing liquid to polish the computer magnetic head, and found that the surface smoothness of the magnetic head was greatly improved after polishing. The measured surface roughness at this time was 0.09~0.40nm, while the surface roughness of the magnetic head was 0.45~0.80nm after polishing with ordinary polishing liquid. Compared with nano-diamond polishing liquid, the effect of nano-diamond polishing liquid is much better, thus the quality of the computer magnetic head is also improved, and we can produce more precision, A computer disk with a larger storage capacity. It is worth noting that when polishing, because the computer and other electronic products most avoid corrosion, so be sure to control the pH of the polishing liquid, the study found that the PH value of the polishing liquid is more appropriate to control between 6.5 and 8. Since the content of anions Cl-and SO2-will determine the pH of the polishing solution, the content of Cl-and SO2-should be controlled when preparing the polishing solution for computer head polishing, and the PH value should be observed at the same time.

super fine polishing problems:

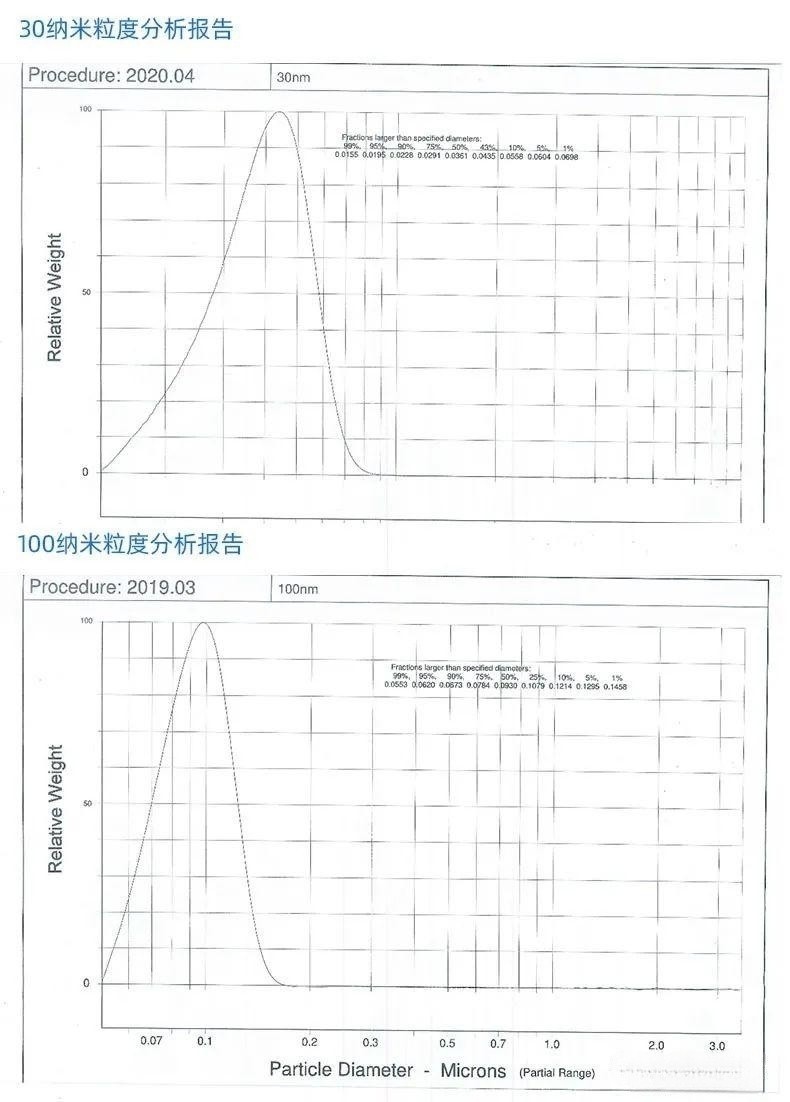

Since nanoparticles have a large specific surface area, they are thermodynamically unstable and tend to agglomerate. After agglomeration, the agglomerates are large and small, some are hundreds of nanometers, and even micron-sized, which will lose the advantages of finer nanoparticles. In this way, in the process of ultra-fine polishing, if there are large aggregates in the polishing liquid, it will damage the surface of the material. Before we know that the spacing of the computer head disk has developed to the nanoscale stage, if the nano-diamond polishing liquid with aggregates is used for polishing, it will cause damage to the disk. Although through the continuous improvement of the process in recent years, the nano-diamond particles in the nano-diamond polishing liquid can be more and more dispersed in the medium for a long time in theory, but through the study found that the nano-diamond particles in the medium still can not be dispersed to the original particle size, so the problem of agglomeration has not been completely solved, and whether these research results can be applied to industrial scale production and whether the quality of nano-diamond polishing liquid can be guaranteed after mass production, whether the storage time will be too short and what the cost will be, these all need further research and experiments to give the answer.

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution