Why does wire cutting process deform? How to avoid it?

Release time:

2023-05-16

1、line cuttingCauses of deformation of machined workpieces

Split a piece of bamboo from the middle, and both halves of the piece of bamboo will bend, most of which bend less and less of which bend more. This is the material itself will have stress, the process of splitting the material to break the original stress balance, through deformation to restore the balance. Wire cutting workpiece deformation is the same reason, the cutting process breaks the original stress equilibrium state of the workpiece.

The deformation of wire cutting is related to the structure of the workpiece. Narrow and long-shaped concave dies and punches are prone to deformation, and the size of the deformation is related to the complexity of the shape and the aspect ratio; workpieces with thinner wall thickness are prone to deformation.

If the deformation is very small, the deformation is almost negligible within the accuracy range required for processing. However, if the deformation exceeds the machining accuracy requirements, it will cause obvious deviation in size and affect the machining shape of the workpiece.

There are many reasons for deformation, such as material problems, heat treatment problems, structural design problems, process arrangement problems, and workpiece clamping and cutting path selection during line cutting. These various reasons will lead to the deformation of the internal stress of the material.

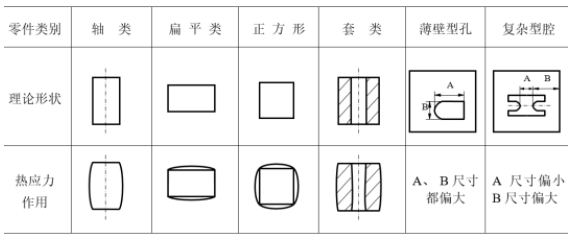

Effect of thermal stress on workpiece shape

2, the workpiece processing deformation prevention measures

Certain measures can be taken to control the deformation of WEDM and prevent the occurrence of deformation.

1) Rough machining or stress release cutting before cutting

If it is necessary to cut a large area on a piece of material, the relative equilibrium state of the internal residual stress of the material will be destroyed, and the material will produce great deformation. We can eliminate most of the stress of the material first, the method is to carry out rough machining (rough machining), remove most of the allowance first, or cut the path to release the stress.

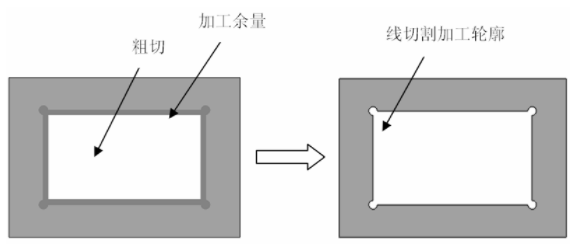

For WEDM processing of large concave dies, two main cuts can be made. First, the offset of the main cut is increased by 0.1-0.2mm on one side for the first main cut to release the stress, and then the standard offset is used for the second main cut, as shown in the following figure.

Rough machining to relieve stress and reduce deformation

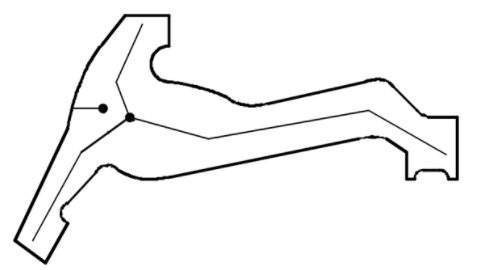

For long narrow shapes, first cut the path to release stress inside this hole, and then process the shape of the hole, as shown in the following figure,

Release stress cutting

2) Processing of threading holes

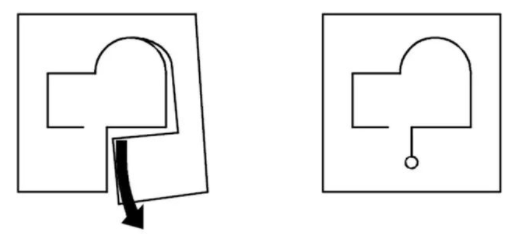

When cutting the punch, if the wire hole is not processed, it is directly cut from the outside of the material, as shown in the following figure (a), the deformation will occur due to the unbalanced stress of the material, resulting in open or closed deformation. The wire hole can be processed on the material for closed contour processing. As shown in the following figure (B), the deformation caused by WEDM can be significantly reduced.

(a) large deformation (B) small deformation

Machining through-wire hole to reduce deformation

2) Optimize the machining path

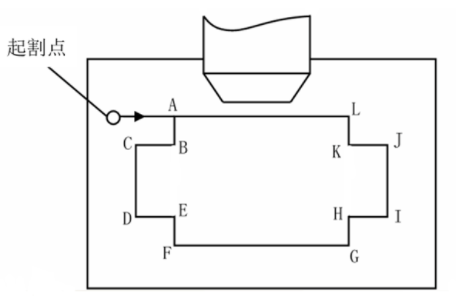

In general, it is best to arrange the machining starting point near the clamping end, the cutting section separating the workpiece from its clamping part at the end of the machining path, and the pause point near the clamping end of the blank. In some processes, due to the unreasonable arrangement of the processing path, it is also the cause of wire cutting deformation. As shown in the figure below, a more reasonable processing path is: A → B → C → D……→ A. If you follow the clockwise direction: A→L→K→J……→A, because the workpiece and the clamping part are cut off at the beginning of cutting, the cutting accuracy of the punch is directly affected by the unreliable factors of clamping when processing to the end of the program.

Arrangement of processing path

4) Multiple cutting

Some workpieces still have some deformation after taking certain measures. In order to meet the accuracy requirements of the workpiece, the traditional habit of cutting to size can be changed and the method of multiple cutting can be used. Fast wire cutting process using multiple cutting method, mainly in order to achieve better surface roughness, but the use of multiple cutting method to reduce the stress caused by the deformation of mold parts has a very important practical significance.

5) Multi-type hole concave template processing process optimization

When the template is processed by wire cutting, with the effect of the original internal stress and the influence of the thermal stress generated by wire cutting, it will produce non-directional and irregular deformation, which will make the thickness of the cutting knife after uneven, which will affect the processing quality and processing accuracy.

In view of this situation, the template with high precision is required in multiple cutting processes. The first cutting will cut off all the waste materials of the type holes. After taking out the waste materials, the automatic shift function of the machine tool will complete the cutting of the type holes in turn: main cutting cavity a, taking the waste materials → main cutting cavity B, taking the waste materials → main cutting cavity c, taking the waste materials →… → main cutting cavity n, take scraps → trim cavity a → trim cavity B →……→ trim cavity n and finish processing.

This cutting method can make each hole have enough time to release the internal stress after processing, and can reduce the mutual influence and micro deformation of each hole due to different processing sequences to a minimum, so as to ensure the processing size accuracy of the template.

However, this process has a large number of threading times and a large workload, which is more suitable for a wire cut machine with an automatic threading mechanism. After cutting, the shape and size meet the requirements of high precision.

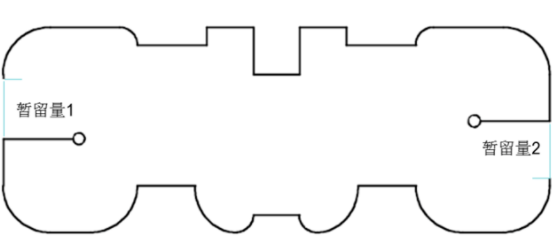

6) Set multi-segment persistence quantity

For the processing of large and complex workpieces, two or more temporary quantities and multiple starting points should be set, as shown in the following figure. When programming, it is processed in an open shape. Before programming, the figure is decomposed into multiple segments and connected in series. When processing, the outline is processed first, and the temporary part is processed finally.

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution