Impurity machine detection method of diamond powder

Release time:

2023-06-02

DomesticDiamondMicro-powderMost of the I-type material of single crystal diamond as raw material, but I-type material.ImpurityHigh content, low strength, can only be used for low-end market product demand. Domestic minoritydiamond powderManufacturers use type II or type III material of single crystal diamond as raw material to produce diamond powder, its processing efficiency is much greater than ordinary diamond powder, to meet the high-end market demand. Diamond powder has high hardness and good wear resistance, and is widely used in cutting, grinding, drilling, polishing and other fields. With the development and progress of science and technology, the market demand for diamond powder is increasing, and the quality requirements are getting higher and higher. For diamond micropowder, the amount of impurities in diamond micropowder directly affects the product quality and performance of micropowder.

1. impurity type

Impurities of diamond powder refers to the non-carbon components in diamond powder, which can be divided into external impurities and internal impurities. The external impurities of the particles are mainly introduced by the raw materials and the production process, including silicon, iron, nickel, calcium, magnesium, cadmium and other elements; the internal impurities of the particles are introduced by the diamond synthesis process, mainly iron, nickel, cobalt, manganese, cadmium, copper and so on. Impurities in diamond powder will affect the surface properties of the powder particles, making the product difficult to disperse. Impurities such as iron and nickel will also cause the product to produce different degrees of magnetism, which will affect the application of micropowder.

2. impurityDetectionMethod

There are many methods for detecting the impurity content of diamond micropowder: including gravimetric method, atomic emission spectrometry, atomic absorption spectrometry, etc. Different detection methods can be selected according to different requirements.

1. Gravimetric method

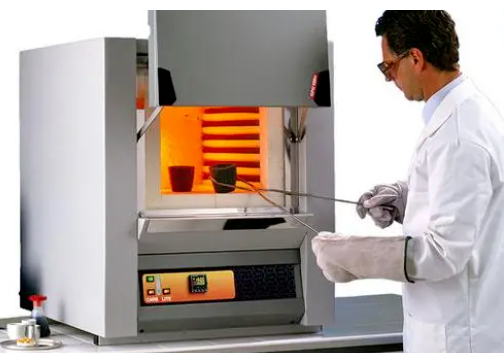

The gravimetric method is suitable for the analysis and detection of total impurity content (excluding volatile substances that can be burned at burning temperature). The main equipment includes muffle furnace, analytical balance, porcelain crucible, dryer, etc. The inspection method for impurity content in the micropowder product standard is high-temperature ignition loss method: sample and add the sample to be tested according to regulations, put the sample to be tested into a crucible with constant weight, place the crucible containing the sample to be tested in a muffle furnace and burn at 1000 ℃ to constant weight (the temperature allows 20 ℃), the residue weight is the impurity mass, and calculate the weight percentage.

2. Atomic emission spectrometry, atomic absorption spectrometry

Atomic emission spectrometry and atomic absorption spectrometry are suitable for qualitative and quantitative analysis of trace elements.

(1) Atomic emission spectrometry: It is an analytical method for qualitative or quantitative analysis of elements by using the characteristic radiation generated by the electronic transition from the excited state to the ground state under the external energy excitation of the atoms of various chemical elements. About 70 elements can be analyzed by atomic emission method. In general, for the determination of components below 1%, can accurately measure the ppm level of trace elements in diamond powder, this method is the optical analysis method to produce and develop the earliest one. Atomic emission spectrometry has played an important role in the qualitative and quantitative analysis of various materials in modern times. It has the advantages of multi-element simultaneous detection ability, fast analysis speed, low detection limit and high accuracy.

(2) Atomic absorption spectrometry: When the radiation emitted by a specific light source passes through the atomic vapor of the element to be measured, it is absorbed by its ground state atom, and the degree of absorption can be measured for elemental analysis.

Atomic absorption spectrometry and atomic absorption spectrometry can make up for each other and cannot be replaced by each other.

A high frequency inductively coupled plasma emission spectrometer

3. factors affecting the measured value of impurities

1. Influence of sampling amount on test value

In actual operation, it is found that the sampling amount of diamond powder has a great influence on the test results. When the sampling amount is 0.50g, the average deviation of the test is large; when the sampling amount is 1.00g, the average deviation is small; when the sampling amount is 2.00g, the deviation is small, but the test time increases and the efficiency decreases. Therefore, when measuring, blindly increasing the amount of sampling does not necessarily improve the accuracy and stability of the analysis results, and will greatly extend the operation time and reduce work efficiency.

2. Effect of particle size on impurity content

The finer the particle size of the diamond powder, the higher the impurity content in the powder. The average particle size of 3 m to fine diamond powder in the production, because of the fine particle size, some of the raw materials in the inclusion of acid and alkali insoluble material is not easy to separate, and thus precipitated into fine particle size powder, so that the impurity content increased. Furthermore, the finer the particle size, the more processes in the manufacturing process, the more impurities brought in from the outside, such as dispersants, sedimentation liquids, dust pollution of the production environment and other impurities.

In the study of the impurity content test of micropowder samples, we found that more than 95% of the coarse-grained diamond micropowder products have impurity content below 0.50, and more than 95% of the fine-grained micropowder products have impurity content below 1.00. Therefore, in the quality control of micropowder, it is stipulated that the impurity content of fine micropowder of 3μm should be less than 1.00; The impurity content of coarse micropowder of 3μm should be less than 0.50; And the impurity content data in the standard should retain two decimal places after the decimal point. Because with the advancement of micropowder manufacturing technology, the impurity content in micropowder will gradually decrease, and a large part of coarse-grained micropowder has an impurity content below 0.10%. If only one decimal place is retained, its quality cannot be effectively distinguished.

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution