Rough purification process of diamond powder

Release time:

2023-06-06

UsuallyDiamondMicro-powderMost of the raw materials are low-grade RVD diamond or explosion synthesis.diamond powderThe raw material itself contains a small amountGraphite, catalyst metal and pyrophyllite and other impurities. At the same time, a large number of metal impurities will be introduced in the later process of crushing and shaping. High impurity content will reduce the overall hardness of diamond and affect the performance of deep processing tools. In order to meet the requirements of the subsequent classification process for product purity, these impurities must be removed before transferring to the classification process.

At present, chemical removal and electrolysis are commonly used.PurificationTechnology for the purification of artificial diamond powder. The latter is mainly used when there are more alloy catalysts in diamond materials to achieve the purpose of recovering catalyst metals. However, in practical work, due to the slow dissolution of alloy catalyst and low production efficiency, it is difficult to adapt to the requirements of production development. In contrast, the chemical method according to the different chemical characteristics of impurities in diamond, the use of different chemical reagents to deal with impurities, respectively, can obtain a better purification effect, that is, the industry commonly used in the "three except" process: acid except alloy catalyst, strong oxidant except graphite, alkali pyrophyllite and other three stages of work. According to the chemical stability of diamond is good, high temperature does not react with acid, strong oxidant characteristics, the general selection of chemical methods for diamond purification. Complete the crushing, shaping process of diamond main impurities for metal, can occur with acid oxidation-reduction reaction of soluble salts, the use of this feature, the use of suitable acid treatment, you can remove most of the metal impurities, but also can remove impurities such as graphite.

Generally, the operation method of acid treatment is: weigh a certain amount of diamond micropowder, put it into a 5000 ml glass beaker or other containers with acid resistance and high temperature resistance, add appropriate amount of acid solution, place the beaker on the electric heating plate or industrial electric furnace in the fume hood and heat it. As the temperature rises, the reaction gradually becomes violent. After the reaction stops completely, stop heating and withdraw the container from the heat source. After the material is cooled to room temperature, the upper waste acid solution is poured out, washed to neutral, and transferred to the classification process.

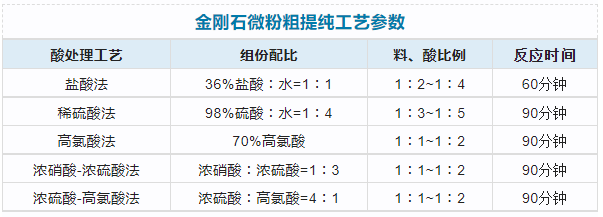

In industrial production, due to the late classification after the completion of the fine purification treatment again, the crude purification process should reduce the cost as much as possible under the premise of meeting the requirements of the classification process, the chemical reagents generally used are mostly industrial pure, the following table is the specific process parameters used in various treatment processes in the crude purification process:

Due to the diamond raw material pyrophyllite and graphite content is less. In order to simplify the treatment process, the general crude purification process is no longer specialized treatment, the product has special requirements, after the completion of the classification of the finished product for post-finishing.

In the production process of diamond powder, various chemical reagents are used in the purification process, and a large amount of harmful gases and wastewater will be discharged during the treatment process, which will endanger the occupational health of operators and pollute the environment. In order to improve the working environment of the operator and reduce the discharge of waste gas and waste water. Some diamond powder production enterprises began to try to change the original purification method, the original open beaker heating process replaced by the use of large closed reactor treatment. The reactor uses electric heating or heat conduction oil indirect heating, the material is quartz glass or lining enamel steel material. According to the production scale can choose 20 liters, 50 liters, 100 liters and other specifications of the reactor, the equipment is equipped with automatic mixing, automatic temperature control, waste gas and absorption and acid vapor condensation reflux device. Reactor purification treatment, not only can increase the amount of a single treatment, reduce labor intensity, but also in energy conservation, improve working conditions and protect the environment effect is remarkable.

Reference materials: "diamond powder" Wang Jing

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution