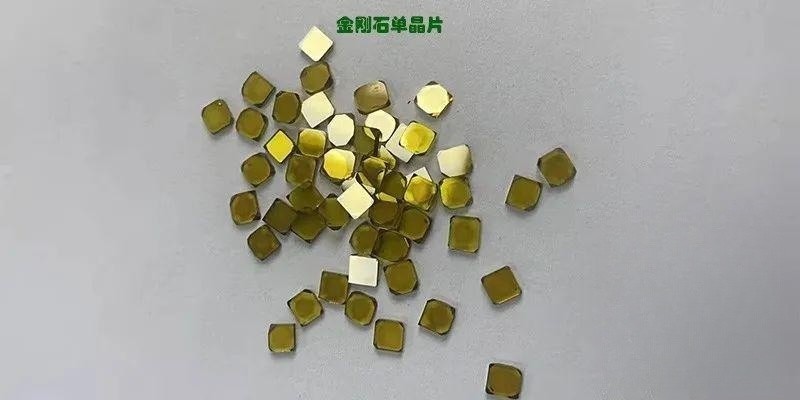

Thermal Conductivity and Application of Diamond Monowafer

Release time:

2023-06-13

The thermal conductivity of diamond is quite good, and it has been applied to many heat dissipation components. For example, the heat dissipation of cpu is coated with a layer of diamond film to speed up its heat dissipation. This is also the odd heat dissipation principle that determines its excellent heat dissipation performance. There are two ways of conducting heat: as in metals, it is mainly the movement of electrons; but in crystals such as diamond, electrons are tightly tied to atoms, and it takes a certain amount of energy to loosen them. At room temperature, there are almost no active electrons. Thus, the conduction of heat is accomplished by the vibrations of the atoms that make up the crystal lattice, which physicists call thermal energy quanta (or phonons). It is possible to imagine the activity of quanta in a diamond lattice as regularly arranged as sports car on a highway. The lattice of C atoms is like a smooth road surface, while the disorderly distribution of C atoms is like a "reducer. There are many factors in crystals that slow down the vibration of phonons, which is why most crystals are not as good conductors of heat as most metals. And diamond is always the exception, in part because diamond is quite pure and can eliminate most scattering effects. As the theory of solids matured in the 1940 s, scientists became interested in the special effects caused by isotopes, in which the presence of different isotopes in the same solid would slow down the vibrations of the quantum of thermal energy in the crystal.

Diamond is the highest thermal conductivity of the material in nature-beyond the metal material, is a good thermal conductor, its thermal conductivity varies, generally 138.16W/(m · K). Type IIa diamond thermal conductivity is particularly good, in liquid nitrogen temperature is 25 times that of copper, the thermal conductivity at room temperature is as high as 2000W/(m · K), 5 times that of copper, with super thermal conductivity.

According to the trace elements contained in diamond can be divided into type I diamond and type II diamond two types. Type II diamond has better thermal conductivity, solution and semiconductor properties, and is mostly used in space technology and cutting-edge industry.

1. The size of diamond single crystal is small, generally below 10mm, which makes it difficult for regular semiconductor inch-level wafer polishing equipment to fix and measure diamond single crystal wafers well.

2. Diamond has high hardness, and the edges and corners of the crystal generated during the processing of the long-term surface will cause obvious physical damage to the regular polishing disc, which will seriously affect the service life of the polishing disc, reduce the polishing removal efficiency, and also bring certain physical scratches to the crystal surface.

3. Chemical mechanical polishing also requires the use of a special redox polishing fluid. For the need to heat the wafer to improve chemical polishing efficiency and reduce polishing time, traditional small semiconductor wafer polishing equipment cannot complete controllable heating. Therefore, special polishing equipment structure design and method are needed to solve the polishing problem of diamond single wafer with millimeter size. Note; article from network

Note; article from network

Focus on hot spots

The main application of diamond powder

Ultra-precision polishing of precision instruments for the use of nanodiamonds

Characteristics of Shandong Metal Powder Hydraulic Press

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution