Factors Affecting Ultra-Precision Grinding and Polishing

Release time:

2023-06-27

In order to achieve sub-nanoscale or even nanoscale processing accuracy, the processing environment supported by ultra-precision grinding and polishing must be strictly controlled. The change of temperature not only affects the geometric accuracy of the grinding machine, but also affects the machining accuracy of the workpiece. Because the temperature of any object is not balanced, it will cause changes in size.

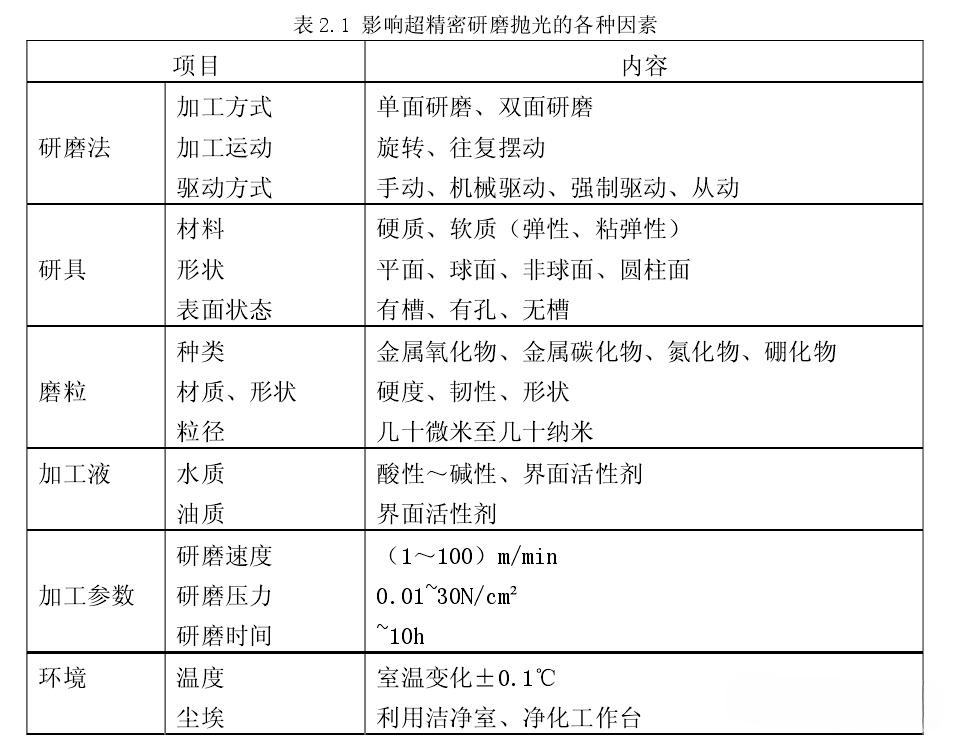

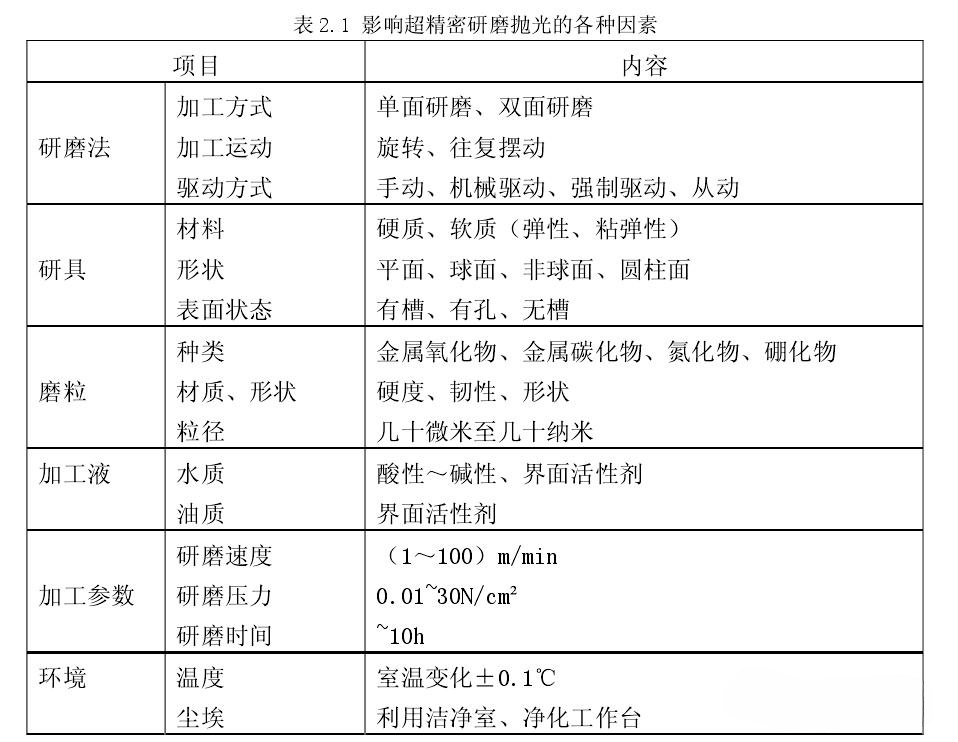

In order to achieve sub-nanoscale or even nanoscale processing accuracy, the processing environment supported by ultra-precision grinding and polishing must be strictly controlled. Table 2.2 lists the environment that constitutes ultra-precision machining and its control items. The influence of air, temperature, humidity and vibration environment on machining will be described in detail below. In ordinary air, there are a large number of dust and particles and other substances, these substances can be ignored in ordinary processing, but the ultra-precision grinding and polishing processing required compared to the accuracy, the size of these dust and particles has become can not be ignored. For example, in the manufacturing process of large-scale integrated circuit components, if the dust in the air is mixed, it is likely to affect the processing accuracy of the components, and become an uncontrollable source of pollution expansion in the subsequent process and affect the final pass rate of the product. Therefore, the cleanliness of the air must be strictly controlled. The change of temperature not only affects the geometric accuracy of the grinding machine, but also affects the machining accuracy of the workpiece. Because the temperature of any object is not balanced, it will cause changes in size. According to statistics, in the ultra-precision grinding and polishing, the error caused by thermal deformation accounts for more than 50% of the total processing error. Humidity is also a key factor in ultra-precision grinding and polishing. Excessive humidity causes corrosion of machine tools and instruments. Low humidity will also make the material brittle and flammable, affecting the machining accuracy and quality. In addition, the internal and external vibration of the system will cause excess relative motion between the tool and the workpiece, which will affect the machining accuracy, the amplitude and frequency of the vibration will also affect the quality of the processing, and the interference of vibration must be eliminated by anti-vibration and vibration isolation measures. Therefore, in the process of ultra-precision grinding and polishing, all external environments must be controlled by measures to prevent changes including air environment, thermal environment, vibration environment, acoustic environment, light environment, electric field and electromagnetic environment from affecting ultra-precision grinding and polishing.

The change of temperature not only affects the geometric accuracy of the grinding machine, but also affects the machining accuracy of the workpiece. Because the temperature of any object is not balanced, it will cause changes in size. According to statistics, in the ultra-precision grinding and polishing, the error caused by thermal deformation accounts for more than 50% of the total processing error. Humidity is also a key factor in ultra-precision grinding and polishing. Excessive humidity causes corrosion of machine tools and instruments. Low humidity will also make the material brittle and flammable, affecting the machining accuracy and quality. In addition, the internal and external vibration of the system will cause excess relative motion between the tool and the workpiece, which will affect the machining accuracy, the amplitude and frequency of the vibration will also affect the quality of the processing, and the interference of vibration must be eliminated by anti-vibration and vibration isolation measures. Therefore, in the process of ultra-precision grinding and polishing, all external environments must be controlled by measures to prevent changes including air environment, thermal environment, vibration environment, acoustic environment, light environment, electric field and electromagnetic environment from affecting ultra-precision grinding and polishing.

Focus on hot spots

The main application of diamond powder

As a kind of super hard abrasive, diamond powder has incomparably superior grinding ability, which has been paid more and more attention by the industrial developed countries. The grinding ability of diamond powder includes the grinding ability of the workpiece and its own wear resistance and crushing resistance, depending on its microhardness, particle size, strength, particle size, and thermal and chemical stability. To sum up, diamond powder used as abrasive has three aspects;

(1) Used in the manufacture of resin-bonded tools, metal-bonded tools, and plating tools.

(2) for industrial, scientific and medical precision or polishing of various precision components.

(3) as a fine abrasive for mold processing, gem polishing processing, gem bearing processing and manufacturing.

In addition to the application of diamond powder as a grinding material, another major use is used as a functional material. For example, the use of its thermal properties and electrical properties. By mixing diamond fine powder into thermosetting resin polymer, cellulose, phenolic resin or ceramic sheet, a new material having improved thermal conductivity and reduced thermal expansion can be produced. The diamond powder mixed to the metal sheet, such as sheet or stainless steel sheet can be made with high thermal conductivity, low thermal expansion and light weight of the new sheet material, in the electronics industry can be made into high-density high-energy devices for thermal control.

From the form of diamond used as grinding materials, according to the relevant data published figures, the world's industrial consumption of more than 60% of diamond powder is used to make diamond plaster, diamond powder mixture and diamond powder grinding fluid.

Ultra-precision polishing of precision instruments for the use of nanodiamonds

We add nano-diamond to the medium to make nano-diamond polishing liquid, which is now mainly divided into aqueous polishing liquid and oily polishing liquid.

Because the nano-diamond polishing liquid nano-diamond particles super hard super hard, with it can remove the material surface small uneven, polished material surface roughness can be reduced to nano-level, so that the material surface finish is very high. At present, nano-diamond polishing liquid can be used in semiconductor silicon wafer polishing, computer head polishing, precision ceramic processing, gem polishing, optical glass polishing and other fields.

Nowadays, due to the development of computers, people's requirements for computer storage capacity continue to increase, which makes us want to manufacture larger disks. In recent years, the storage capacity of computer disks has been increasing, but with the increase of storage capacity, the problem is that the gap between the disk and the head is getting smaller and smaller, which is close to 10NM. The surface roughness, scratches and impurity particles of the head and the disk will cause damage to the computer disk. As the distance between the disk and the head has reached the nanometer level, the micron-level polishing liquid has failed to meet the polishing requirements, so only nano diamond polishing liquid can meet the requirements of this aspect. We used nano-diamond polishing liquid to polish the computer magnetic head, and found that the surface smoothness of the magnetic head was greatly improved after polishing. The measured surface roughness at this time was 0.09~0.40nm, while the surface roughness of the magnetic head was 0.45~0.80nm after polishing with ordinary polishing liquid. Compared with nano-diamond polishing liquid, the effect of nano-diamond polishing liquid is much better, thus the quality of the computer magnetic head is also improved, and we can produce more precision, A computer disk with a larger storage capacity. It is worth noting that when polishing, because the computer and other electronic products most avoid corrosion, so be sure to control the pH of the polishing liquid, the study found that the PH value of the polishing liquid is more appropriate to control between 6.5 and 8. Since the content of anions Cl-and SO2-will determine the pH of the polishing solution, the content of Cl-and SO2-should be controlled when preparing the polishing solution for computer head polishing, and the PH value should be observed at the same time.

Characteristics of Shandong Metal Powder Hydraulic Press

Shandong metal powder hydraulic press is suitable for automatic control molding of powder dry pressing. It is widely used in electronics, powder metallurgy, soft magnetic industry, conductive dry pressing molding, chemical industry, automobile manufacturing, medicine, energy and environmental protection industry, toy industry, etc. Suitable dry-pressed powders include ferrous and non-ferrous metal powders, electronic ceramic powders, ferrites, rare earth powders, cemented carbide powders, PTFE, diamond and graphite powders, and the like.

The hydraulic transmission system of Shandong metal powder hydraulic press is composed of power mechanism, control mechanism, actuator, auxiliary mechanism and working medium. The power mechanism usually uses an oil pump as the power mechanism, and is generally an integrated oil pump. One or more oil pumps are selected in order to meet the speed of movement of the actuator. Low pressure gear pump; medium pressure vane pump; high pressure piston pump. The pressure processing and forming of various plastic materials, such as the extrusion, bending, drawing of stainless steel plates and steel plates, and the cold pressing of metal parts, can also be used for the pressing of powder products, grinding wheels, bakelite and resin thermosetting products.

Unlocking Efficiency: The Full Digital Servo Hydraulic Press Revolution

Discover how thefull digital servo hydraulic press is transforming industries with precision and efficiency.